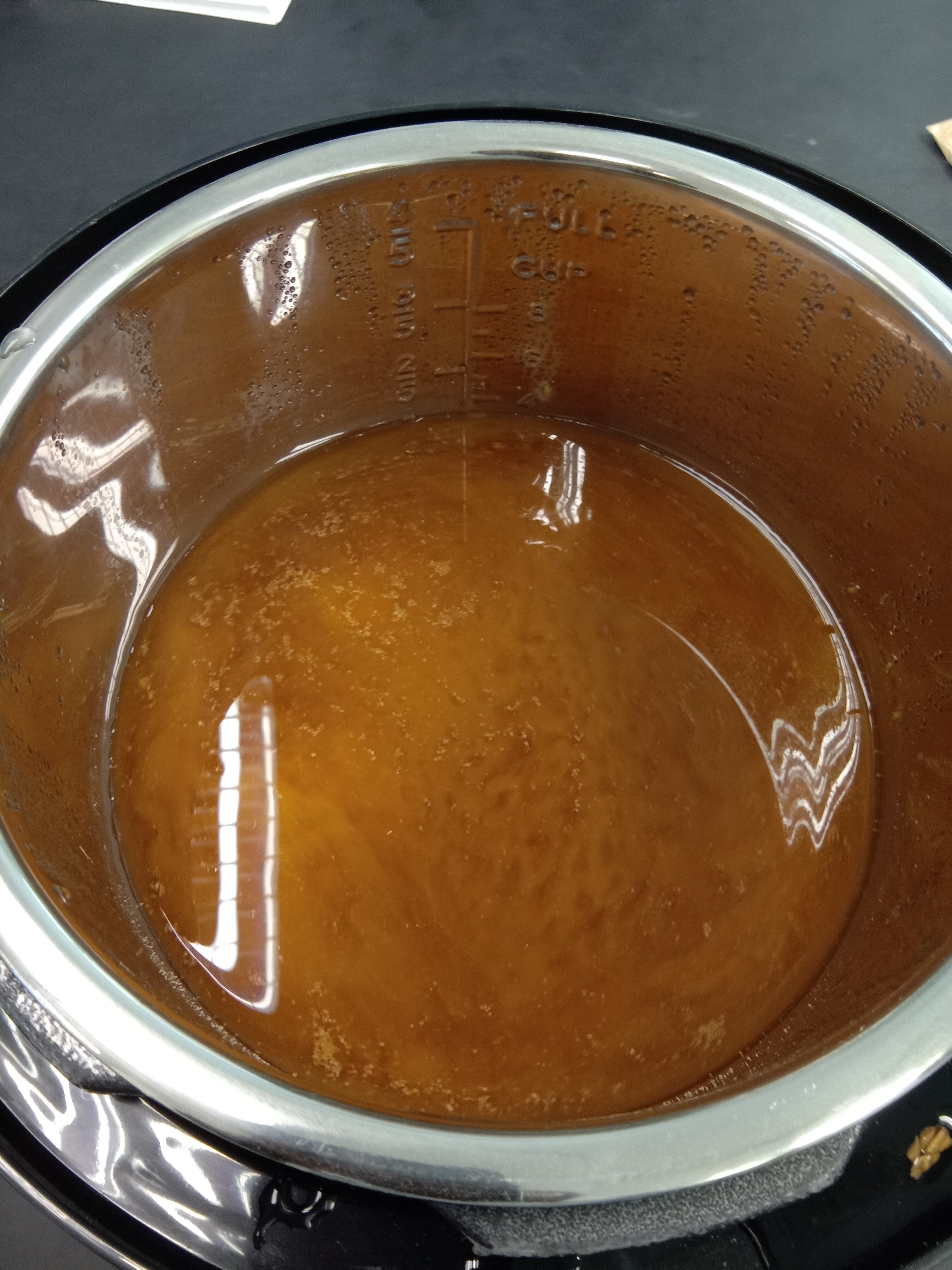

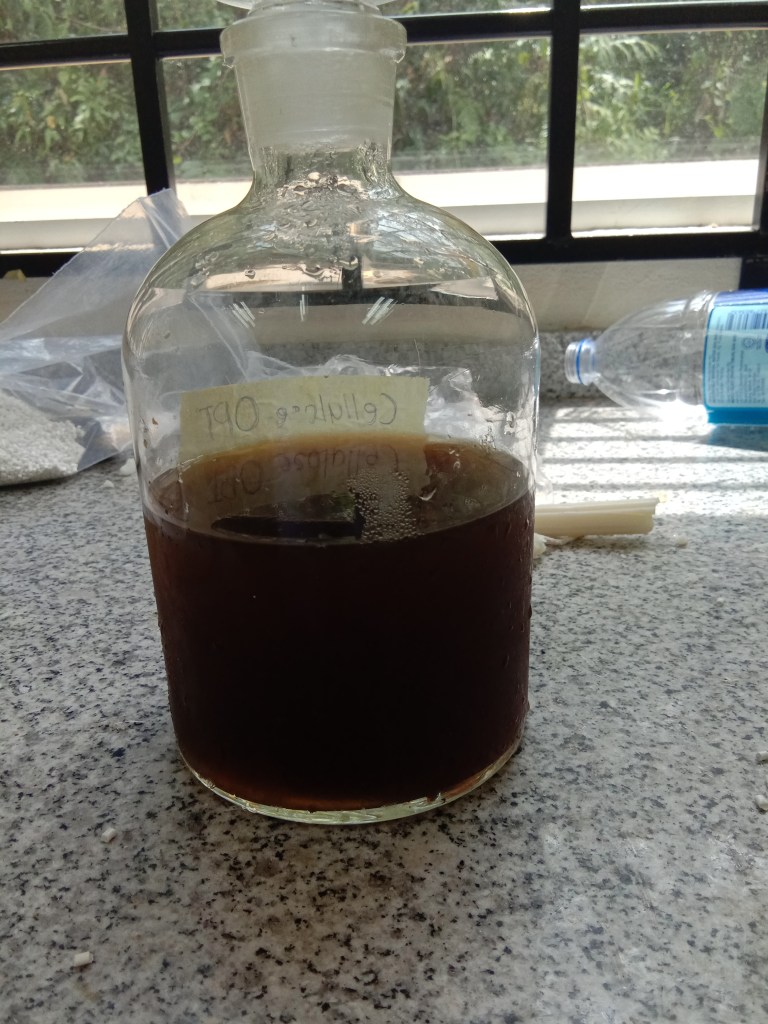

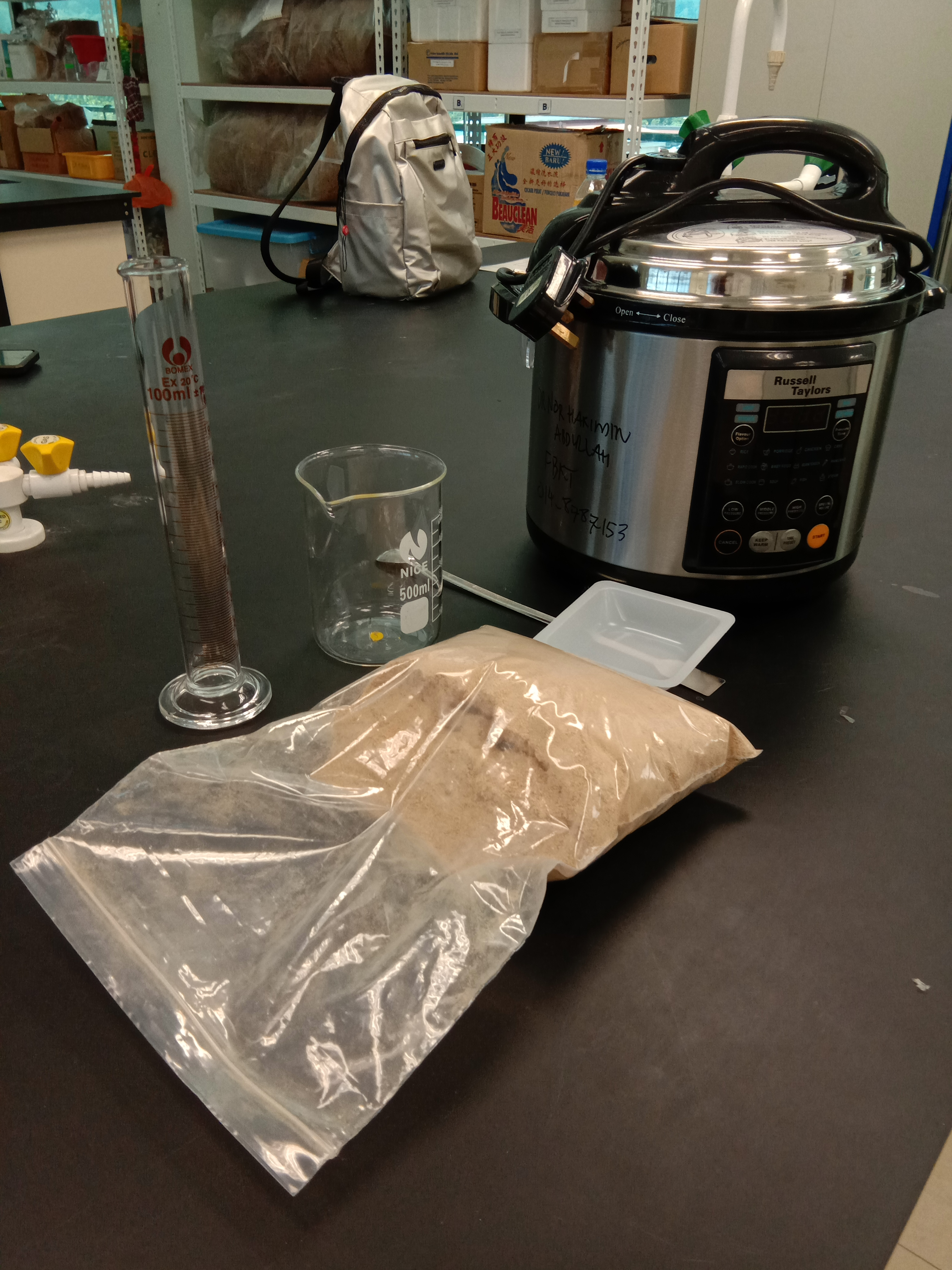

Our group had decided to use PVC-cellulose as the main materials in the making of robotic car. The first step that we need to do is that the cellulose extraction from oil palm trunk. The extraction of cellulose only needs a simple process where the OPT will be dissolved in the distilled water. They will be cooked in the pressure cooker for an hour.

The cellulose extraction step:

Materials: OPT powder, Distilled water

Apparatus: Pressure cooker, 1000ml beaker, spatula and measuring cylinder.