Dear Dr Hakimin,

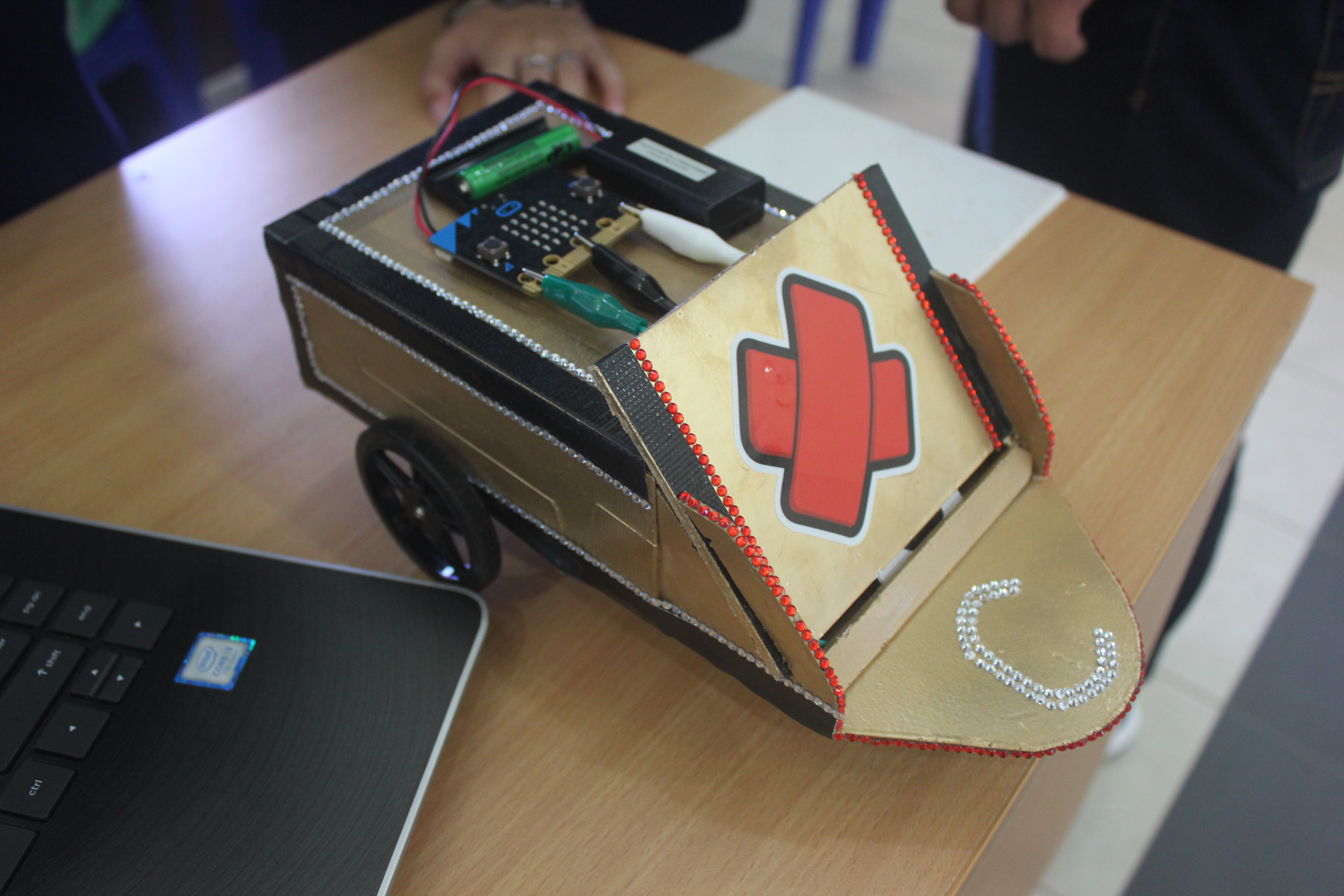

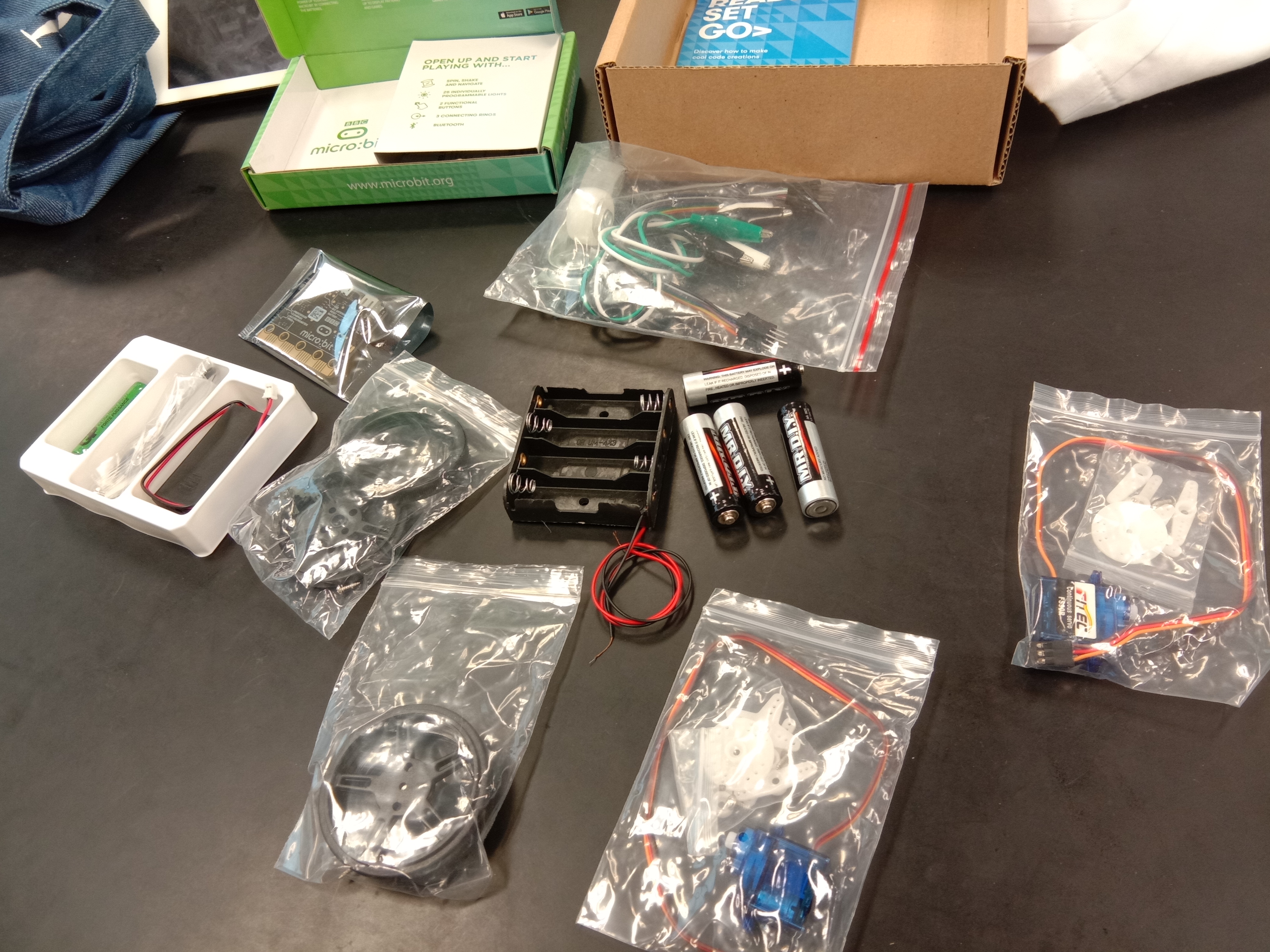

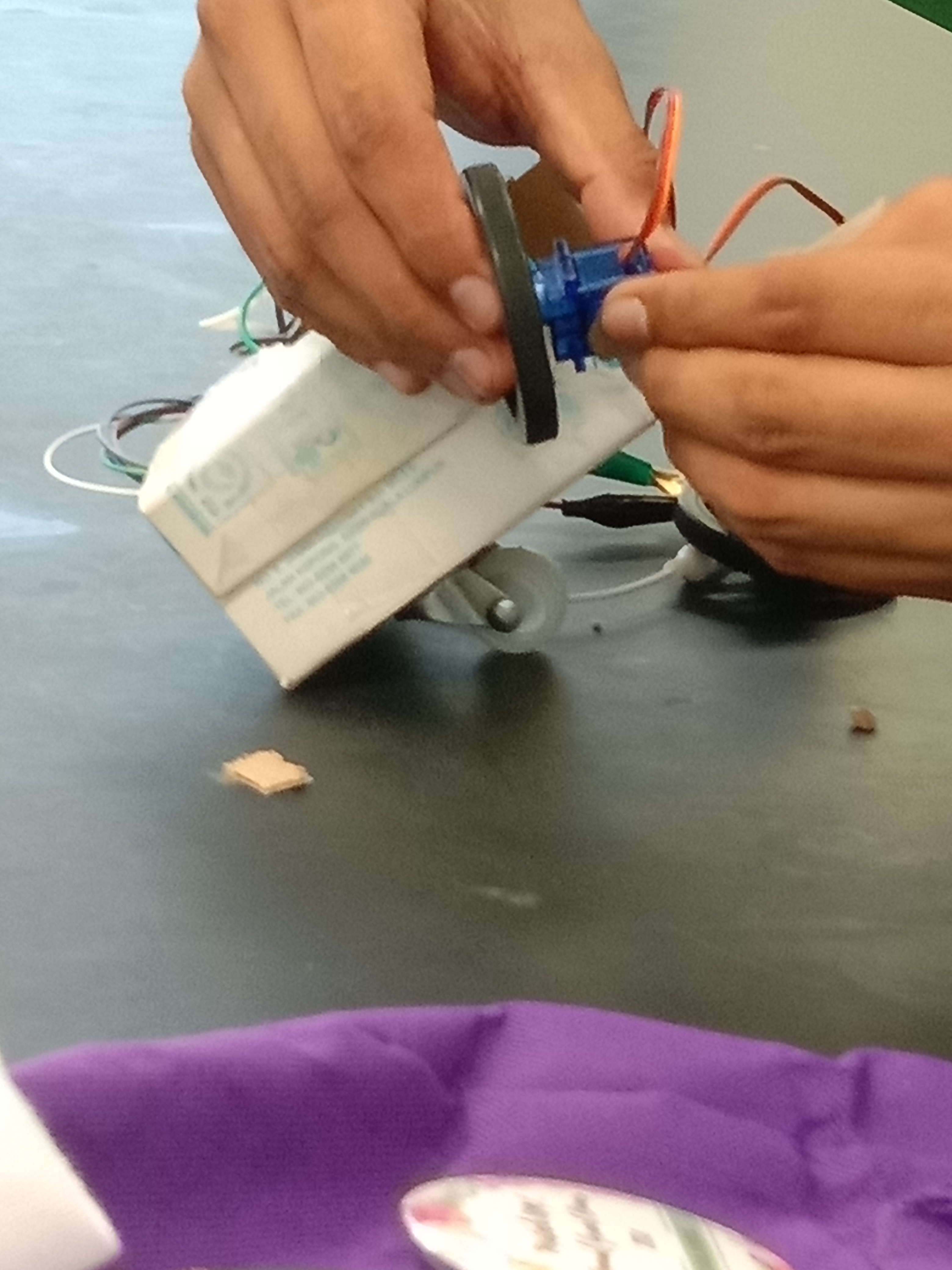

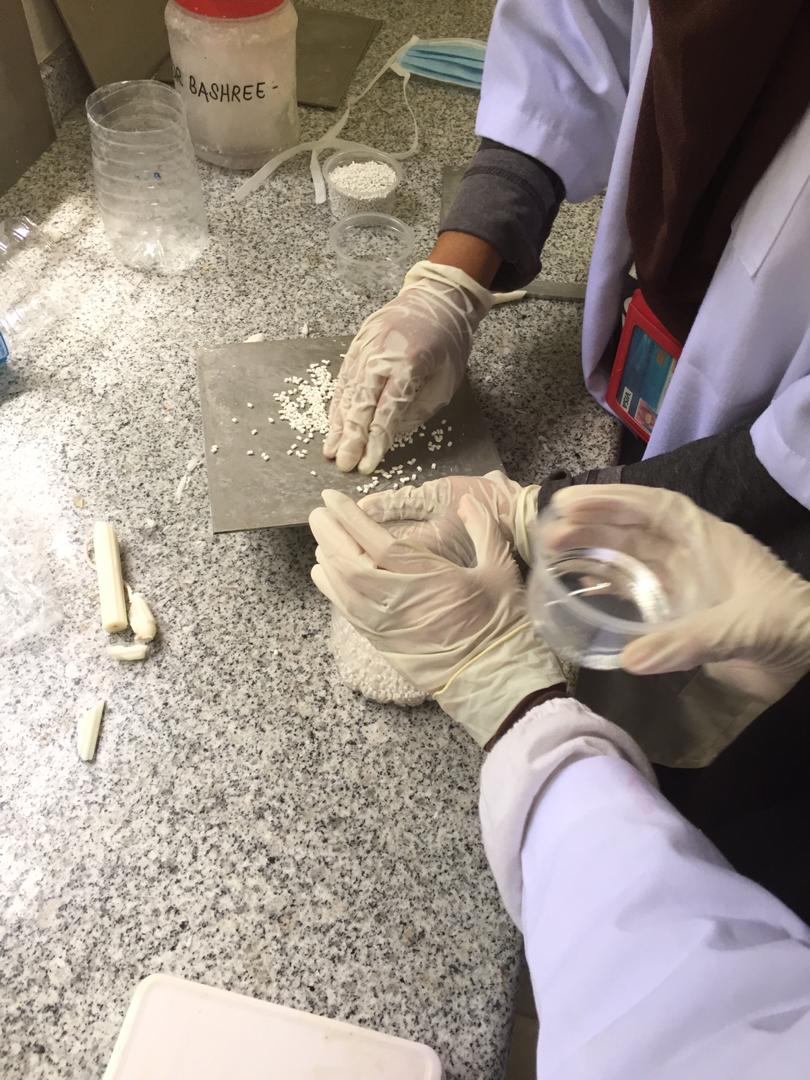

Thank you for creating this event which is the robocar racing day. It was a new experience for most of us and I believe that all of the SEB 3 will remember this memory untill forever. Thank you Dr Hakimin for all of the guidance and knowledge that had being shared to all of us. We will miss Dr Hakimin so much after this. Once again, thank you Dr Hakimin.

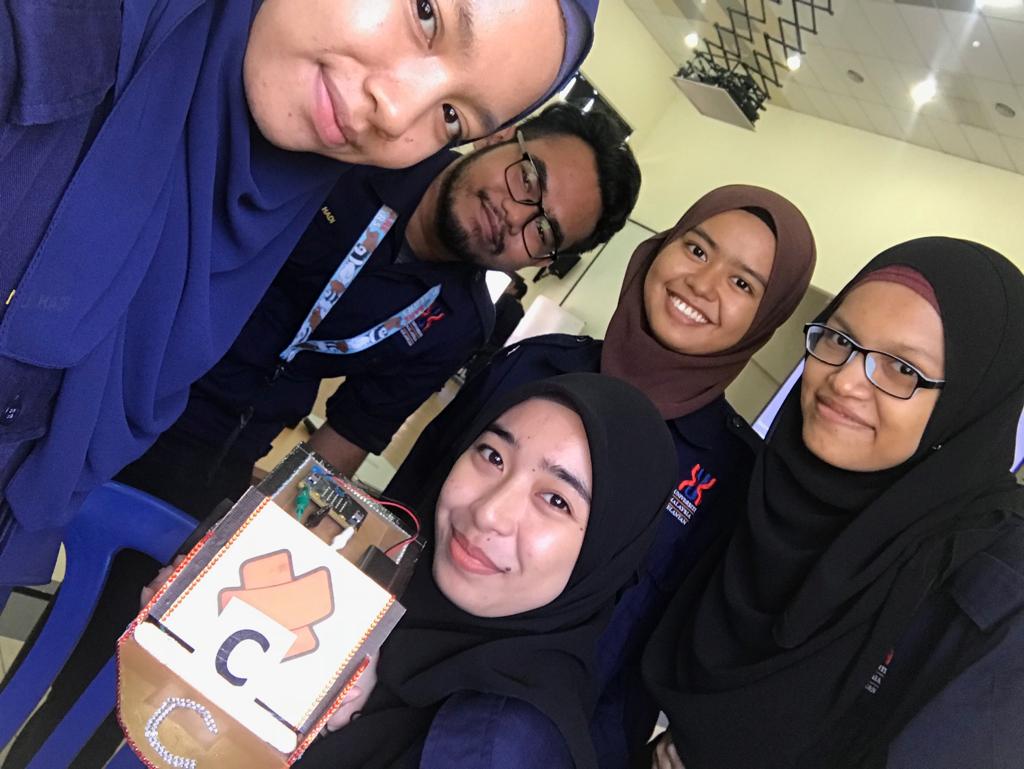

Thank you for being a good teammates. Thank you for all the knowledge and team works that everyone contribute in this project. Yes, we do have a misunderstanding but still we nailed it. This can be proved by being a second best group among ten groups that taking part in this racing. I LOVE YOU GUYS SO MUCH AND I WILL REMEMBER YOU GUYS TILL FOREVER.

LOVE,

SYIDA, ASIKIN, ATIKAH, HAZRYNA AND REDZA…